Capping a two-faced particle gives duke engineers complete control

Advertisement

Scientists drew fittingly from Roman mythology when they named a unique class of miniscule particles after the god Janus, who is usually depicted as having two faces looking in opposite directions.

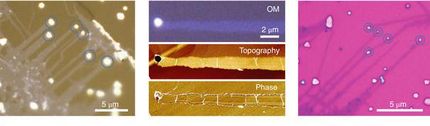

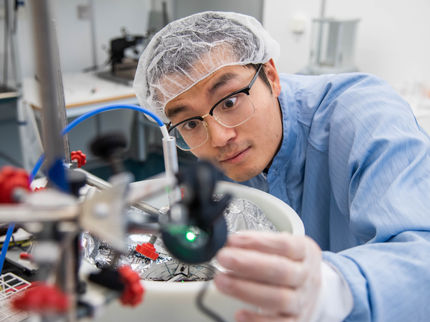

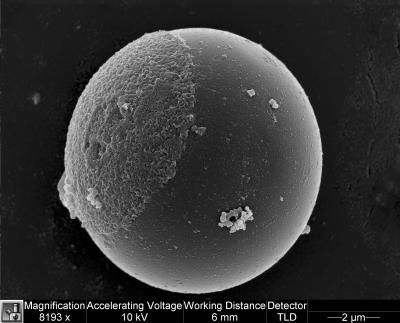

This is a Dot-Janus particle.

Ben Yellen, Duke University

For years, scientists have been fascinated by the tantalizing possibilities of these particles for their potential applications in electronic display devices, sensors and many other devices. However, realizing these applications requires precise control over the positions and orientation of the particles, something which has until now eluded scientists.

Duke University engineers say they can for the first time control all the degrees of the particle's motion, opening up broad possibilities for nanotechnology and device applications. Their unique technology should make it more likely that Janus particles can be used as the building blocks for a myriad of applications, including such new technologies as electronic paper and self-propelling micromachines.

Typical Janus particles consist of miniscule spherical beads that have one hemisphere coated with a magnetic or metallic material. External magnetic or electric fields can then be used to control the orientation of the particles. However, this coating interferes with optical beams, or traps, another tool scientists use to control positioning.

The breakthrough of Duke engineers was to devise a fabrication strategy to coat the particle with a much smaller fraction of material. This discovery allows these particles to be compatible with optical traps and external magnetic fields, allowing for total control over the particles' positions and orientations.

"Past experiments have only been able to achieve four degrees of control using a combination of magnetic and optical techniques," said Nathan Jenness, a graduate student who completed his studies this year from Duke's Pratt School of Engineering. He and co-author Randall Erb, also a graduate student, were first authors of a paper appearing online in the journal Advanced Materials. "We have created a novel Janus particle that can be manipulated or constrained with six degrees of freedom."

The researchers have dubbed the unique particles they created "dot-Janus" particles.

Using optical traps on dot-Janus particles, researchers controlled three degrees of movement – up and down, left and right, forward and backward, while constraining one degree of rotation - side-to-side tilting. Using magnetic fields, they controlled the remaining two degrees of rotation - forward and backward tilting, and left and right turning.

"The solution was to create a particle with a small cap of cobalt that covers about a quarter of the particle," Erb said. He and Jenness conducted their research in the laboratory of Benjamin Yellen, Duke assistant professor of Mechanical Engineering and Materials Science. "This gave the particle just enough of a magnetic handle to allow it to be manipulated by magnetism without interfering with the optical tweezers."

The researchers said that the fabrication of these unique dot-Janus particles combined with the ability to control their orientation will have important ramifications in the burgeoning field of nanoengineering.

"Being able to more completely control these particles affords us a greater ability to measure the mechanical properties of biomolecules, including DNA," Yellen said. "It may also be possible to control the behavior of cells by manipulating dot-Janus particles attached to cell surfaces. These biological applications, as well as the ability to control the assembly of nanostructures, establish the broad scientific value of these findings."

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.