Successful Field-Trial Remediation of 1,2-DCA and VC Contaminated Groundwater in Northern Italy

The Adventus Group announced that laboratory and field tests recently conducted in Italy resulted in its patented EHC® In Situ Chemical Reduction (ISCR) biotechnology being selected for its ability to meet vendor claims and client expectations for an effective, cost-efficient remedial strategy. The environmental engineering firm of Gruppo TRS conducted extensive testing, and presented their findings at the BOSICON 2009 International Conference on Remediation of Polluted Sites in Rome, Italy.

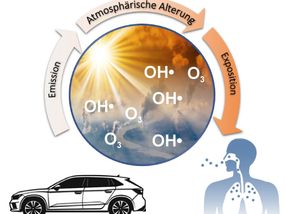

The presentation described rigorous laboratory and field tests conducted to select and optimize an in situ remedial design for a large, complex site located inside an operating petrochemical plant in Northern Italy. The subsurface environment at the site is impacted by 1,2-dichloroethane (1,2-DCA) and vinyl chloride (VC) about 300,000 and 500 µg/L in groundwater, respectively. Knowing the general persistence of 1,2-DCA in the environment, initial laboratory tests evaluated various remedial technologies: two different chemical oxidants (ISCO) and biochemical anaerobic reduction (ISCR). Of the two oxidants tested, only the activated persulfate was effective; RegenOx showed no activity whatsoever. Although the ISCR reactions required a longer treatment time, both 1,2-DCA and VC were completely removed in less than sixty days, without the accumulation of dead-end catabolites.

The use of EHC for ISCR was subsequently chosen for field-scale test, considering its minimal geochemical impact on soil and groundwater conditions. The initial field test area was ca. 50 m2 and the total volume of saturated soil treated was ca. 700 m3. A total of 6,300 kg of EHC amendment was injected through nine injection points using direct-push technology. Groundwater monitoring from four proximal observation wells showed a widespread and sustained reduction in redox (Eh -150 mV to -450 mV) and, most significantly, within ca. 9 months the groundwater concentrations of both 1,2-DCA and VC were reduced from ca. 800,000 µg/L to in to below the regulatory treatment standards (SSTL) of 1,500 µg/L, with two of the monitoring wells containing < 10 µg/L 1,2-DCA.

Design of full-scale site remediation using the EHC ISCR technology is being completed. Simultaneously, continued monitoring of the field site t time on-going to verify the effective reagent life and document lack of “rebound” which is typical for many other remedial technologies. Full scale implementation will employ 600 to 700 tonnes of EHC to treat an area measuring 7,000 m2 and is planned for 2009 through 2011

Most read news

Organizations

Other news from the department research and development

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.