Uhde and Solvay agree to collaborate in the field of brine preparation for electrolysis plants

Uhde and the internationally active Brussels-based Solvay group have agreed to collaborate in the field of brine preparation for chlor-alkali electrolysis plants.

“The aim of our partnership is to offer our customers all-round more efficient production processes for chlorine and caustic soda solution which at the same time protect the environment by reducing emissions,” explained Dr. Benno Lüke, Head of Uhde’s Electrolysis division.

“The partnership with Uhde creates a win-win situation“, says Jean-François Serrier, Head of Solvay’s Intellectual Assets Management. “Granting a non-exclusive license to use our more energy-efficient and environment friendly Solvay-patented technologies is good for both companies and Uhde can now implement our technology on a wide scale and so help to reduce greenhouse gas emissions in the chlor-alkali industry.”

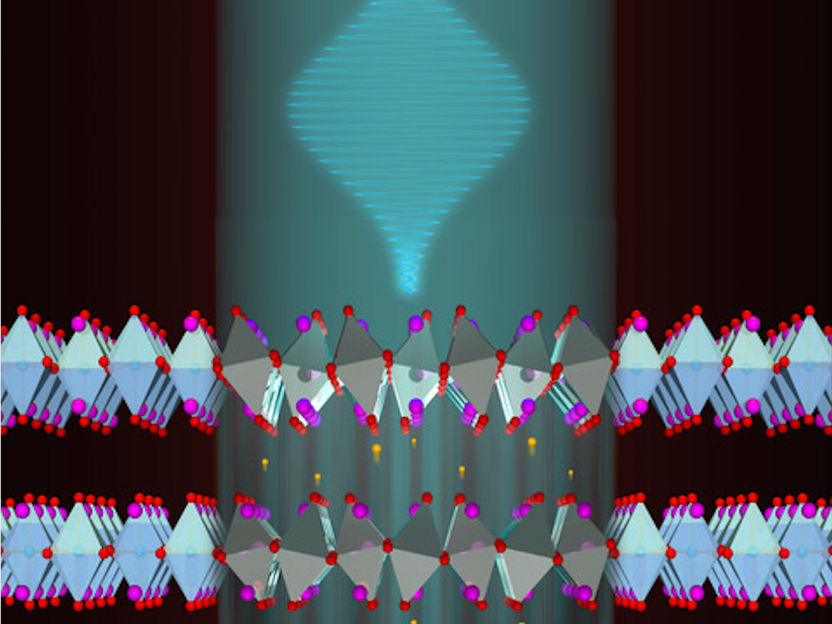

The two field-tested Solvay-patented technologies which Uhde will in future offer its customers concern the respective removal of iodine and chlorate from the brine (NaCl or KCl salt solution), the main feedstock for chlor-alkali electrolysis. If the original brine has a gram-per-litre chlorate concentration in a single-figure range, the chlorate removal process reduces this by means of a catalytic process to a level of less than 20 milligrams per litre.

Salt deposits which contain large amounts of iodine, such as those found in China, India and the USA, also hinder the achievement of optimum production results. “It was therefore important for us to be in a position to offer our customers available technologies to counter this problem,” said Dr. Lüke.

Most read news

Topics

Organizations

Other news from the department business & finance

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

MediLoc Laborsysteme GmbH - Minden, Germany

Panaeolus_cambodginiensis

Taking the stress out of magnetic field detection

Research to enable cheaper and safer battery storage - New insights into batteries during operation

Richard_D._James

Category:Clathrates

Gloria_Niemeyer_Francke

Shaking off the correlated-electron traffic jam