To use all functions of this page, please activate cookies in your browser.

my.chemeurope.com

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

- My watch list

- My saved searches

- My saved topics

- My newsletter

Oxyhydrogen

The flame is hottest in the burning of a stoichiometric mixture. It is less hot when there is an excess of oxygen or hydrogen, or when an inert gas such as nitrogen is mixed in, because there the same amount of heat is added to a larger amount of matter. Oxyhydrogen is usually made from water electrolysis, which also ensures a stoichiometric proportion. At normal temperature and pressure, oxyhydrogen can burn when it is between about 4% and 94% hydrogen by volume.[1] Although, if the gas velocity out of a torch tip is too great, there will be ignition difficulty as the flame will tend to blow itself out. Oxyhydrogen explosions can be a hazard where water electrolysis happens unintentionally, for example in large lead-acid batteries. Oxyhydrogen cannot safely be stored at useful pressures because of its explosive nature. Relatively low pressures can be achieved, allowing the application to pressurized torches. Product highlight

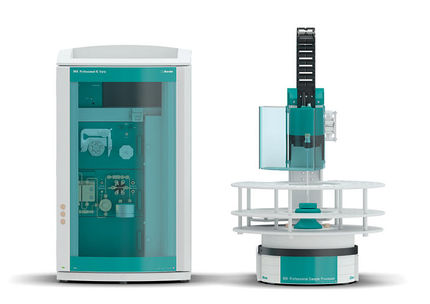

Oxyhydrogen torch

An oxyhydrogen torch is an oxy-gas torch which burns hydrogen (the fuel) with oxygen (the oxidiser). It is used for cutting and welding metals, glass, and some plastics.[2] A water torch is an oxyhydrogen torch which is fed by oxygen and hydrogen generated on demand by water electrolysis, avoiding the need for supplied oxygen and hydrogen. [1]. It is used in small-scale applications such as making jewelry and electronics, and other oxyhydrogen torch applications. An oxyhydrogen flame is used in the glass industry for "fire polishing", i.e. slightly melting the surface of glass to remove scratches and dullness. Another application is in forming preform blanks via chemical vapor deposition in making fiber optics. Oxyhydrogen torches are also used in the ceramics and sensor industry, where the temperature and velocity of the flame is beneficial. Oxyhydrogen torches must be designed to mitigate flashback by making the electrolytic chamber strong enough; an intermediary water bubbler makes potential electrolyzer damage from flashback negligible, and also captures any remaining electrolyte (sodium or potassium hydroxide) in the output gas. A flashback arrestor is useless due to the flame velocity. Some water torch models mix the two gases immediately after production (instead of at the torch tip) making the gas mixture more accurate; this electrolyzer design is called common ducting. Common ducted electrolyzers are typically series cell parallel plate design, but can also be built using cylindrical cells. The main criteria for common ducting is a single gas output hose. Oxyhydrogen gas produced this way is sometimes called Brown's gas (see below). Oxyhydrogen gas produced in an independently ducted electrolyzer is not considered Brown's Gas. Independently ducted electrolyzers have substantially separated anodes and cathodes, are typically rod type design, and have separate hydrogen and oxygen gas output hoses. Old usesMany forms of oxyhydrogen lamps have been invented, but the explosiveness of the gas mixture made them all more or less dangerous at that time.

Brown's gas

Brown's gas, as presented by Yull Brown and subsequent investigators is a mixture of science and pseudoscience. Hoaxes are also claimed to be associated with Brown's gas due to a sourceless distinction from the water fuel cell; although, the lack of a defined relationship establishes a reasonable distinction in itself. Overall, considering the original claims of Yull Brown and those of subsequent investigators, Brown's gas is a sometimes overly hyped technology conforming with standard electrolysis parameters. Many of the claims about the gas[3] are well-understood properties of oxyhydrogen, including Atomic welding: "An electric arc is passed through the mixture of gas before burning, so that the gas molecules break into atomic oxygen and hydrogen, using the electrical energy to produce a hotter flame when the atoms recombine". DesignA Brown's Gas electrolyzer comprises "the cells as a single unit in which a number of electrodes, effectively in series, are arranged adjacent each other in a common electrolytic chamber, the chamber being provided with a gas collection space and an outlet for connection to, for example, gas burner means. Furthermore, only the end electrodes need be connected to an external source of electrical energy and the arrangement as a whole can be made extremely efficient and compact. Additionally the need for a transformer for most applications can be eliminated by such an arrangement so that the apparatus can be designed to be electrically connected directly to a main electrical supply, through a bridge rectifier if desired. By eliminating the need for a transformer, the gas generating equipment as a whole can be made surprisingly compact, to be well suited for small domestic requirements as well as heavy industrial requirements". [4] Electrolytic cells arranged in series experience voltage division. The successive addition of subsequent cells will reduce the voltage across each cell accordingly. Conversely the removal of subsequent cells increases the voltage across each individual cell. The current passing through the entire cell arrangement can be limited with the properties of a capacitor. The current through a capacitor is proportional to the change in voltage with respect to time, multiplied by the specific capacitance value. Therefore the current passing through the capacitor can be addressed by modifying the frequency of the voltage source. Having less total power delivered, to each individual cell, reduces the reaction temperature. Too many cells and the voltage across each cell will not be enough to sustain reasonable current flow. Too few cells and the voltage across each individual cell will be too high, and the water can reach boiling temperature. In a parallel cell electrolyzer current division occurs. Because electrolysis is a current driven reaction the addition of subsequent cells reduces the quantity of current delivered to each individual cell, thus proportionally reducing the degree of the electrolytic reaction. George Wiseman believes "that anything above 2.2 volts won't make much Brown's Gas" [5] This is referring to the voltage across each individual cell, and not the entire cell apparatus. Keeping the voltage at such a relatively low value will mitigate waste heat associated with an unnecessarily high electrolytic reaction temperature. Minimizing waste heat will increase overall efficiency. Overall "as a good rule of thumb. If your electrolyzer stays fairly cool during heavy power, you are likely making Brown's Gas".[6] Since Brown's Gas is produced by minimizing the voltage across each individual cell, it production is more efficient than other oxyhydrogen electrolyzer designs. Applications

Foundational Information

Claims

HHOHHO gas or Klein gas is an oxyhydrogen mixture made by water electrolysis and has been trademarked Aquygen by the firm Hydrogen Technology Applications. Claims

References

This article incorporates text from the Encyclopædia Britannica Eleventh Edition, a publication now in the public domain. Categories: Chemical processes | Hydrogen | Fuels |

|||

| This article is licensed under the GNU Free Documentation License. It uses material from the Wikipedia article "Oxyhydrogen". A list of authors is available in Wikipedia. |