Scientists Crack Secret Strength of Silk

Tufts University Bioengineers figured out how spiders and silkworms spin such strong silk, which could have far-reaching implications for everything from hospital dressings to body armor.

While humans have relied on silk for more than 2,000 years, scientists have never been able to unravel the mystery of how spiders and silkworms produced their incredibly strong fibers - until now. In a newly published study, Tufts researchers discovered the mechanism for production of strong silk, providing critical new information about nature's strongest fiber.

"The entire process is controlled by the amount of water, which is so simple," Tufts' David Kaplan, a professor of biomedical engineering who led the research team, told Reuters.

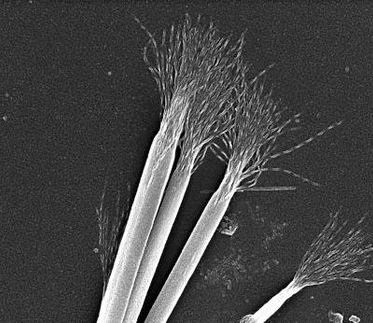

Spiders and silkworms both produce silk from a gel-like solution of proteins which is spun into silk fibers. Scientists have previously tried to replicate the process using similar protein solutions, but were never able to produce fibers with the same strength as real silk.

According to the Tufts team, spiders and silkworms regulate the mixture of water and proteins, controlling the entire process. The discovery helps explain how spiders and silkworms kept the gel-like proteins from solidifying too quickly, resulting in a permanent block in the organism's spinning system.

"Kaplan and Hyoung-Joon, a postdoctoral fellow, copied the process in the lab, creating silk fibres by smearing the gel between sheets of glass," reported the Canadian Broadcasting Corporation.

The Tufts research, which was published Thursday in the international science journal Nature, could give scientists a new approach to creating artificial silk.

"We have identified key aspects to this process that should provide a roadmap for others to optimize artificial spinning of silks as well as in improved production of silks in genetic engineered host systems such as bacteria," reported the Associated Press.

Kaplan says the discovery could have far reaching implications.

"The finding could lead to the development of processing methods resulting in new high-strength and high performance materials," Kaplan, who chairs Tufts biomedical engineering department, told London's Guardian newspaper.

From clothing to military applications, artificial silk could be used to improve a wide range of products.

"[The Tufts scientist said] the new knowledge can be applied to manufacturing high-strength materials like sporting equipment, hiking gear and protective clothing for police and military personnel," reported the Associated Press.

Strong and flexible, silk offers advantages over existing materials like Kevlar and nylon.

"Kevlar, an artificial ballistic protection material used in military apparel, is strong but not very flexible," reported the Associated Press. Nylon is just the opposite: flexible but not strong.

"Silk seems to bridge that gap," Kaplan told the international news service.

Artificially produced silk could also result in new advances in medicine.

"[Over the past two decades,] there's been a real strong interest in whether this unique silk with its very nice mechanical properties of strength and flexibility, can be turned into different fibers, make it into film, use it for organ and tissue repair," Kaplan told the Associated Press.

Kaplan's team - which collaborated with scientists and experts from across the University including colleagues in the chemical, biological and biomedical departments to the veterinary and dental schools - has already begun using silk to repair torn ligaments.

"In 2002, Kaplan and some medical colleagues used silk as a scaffold to grow cells for repairing common injuries to knee ligaments," reported the Canadian Broadcasting Corporation.

Most read news

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.