DNA origami could lead to nano 'transformers' for biomedical applications

Tiny hinges and pistons hint at possible complexity of future nano-robots

If the new nano-machines built at The Ohio State University look familiar, it's because they were designed with full-size mechanical parts such as hinges and pistons in mind. The project is the first to prove that the same basic design principles that apply to typical full-size machine parts can also be applied to DNA - and can produce complex, controllable components for future nano-robots.

In a paper published in the Proceedings of the National Academy of Sciences, Ohio State mechanical engineers describe how they used a combination of natural and synthetic DNA in a process called "DNA origami" to build machines that can perform tasks repeatedly.

"Nature has produced incredibly complex molecular machines at the nanoscale, and a major goal of bio-nanotechnology is to reproduce their function synthetically," said project leader Carlos Castro, assistant professor of mechanical and aerospace engineering. "Where most research groups approach this problem from a biomimetic standpoint - mimicking the structure of a biological system - we decided to tap into the well-established field of macroscopic machine design for inspiration."

"In essence, we are using a bio-molecular system to mimic large-scale engineering systems to achieve the same goal of developing molecular machines," he said.

Ultimately, the technology could create complex nano-robots to deliver medicine inside the body or perform nanoscale biological measurements, among many other applications. Like the fictional "Transformers," a DNA origami machine could change shape for different tasks.

"I'm pretty excited by this idea," Castro said. "I do think we can ultimately build something like a Transformer system, though maybe not quite like in the movies. I think of it more as a nano-machine that can detect signals such as the binding of a biomolecule, process information based on those signals, and then respond accordingly - maybe by generating a force or changing shape."

The DNA origami method for making nano-structures has been widely used since 2006, and is now a standard procedure for many labs that are developing future drug delivery systems and electronics. It involves taking long strands of DNA and coaxing them to fold into different shapes, then securing certain parts together with "staples" made from shorter DNA strands. The resulting structure is stable enough to perform a basic task, such as carrying a small amount of medicine inside a container-like DNA structure and opening the container to release it.

To create more complex nano-machines that could perform such tasks repeatedly, Castro joined with Haijun Su, also an assistant professor of mechanical and aerospace engineering at Ohio State. Combined, the two research teams have expertise in nanotechnology, biomechanics, machine engineering and robotics.

Castro said there are two keys to their unique approach for designing and controlling the machines' motion. The first involves making certain parts of the structure flexible. They make flexible parts from single-stranded DNA, and stiffer parts from double-stranded DNA.

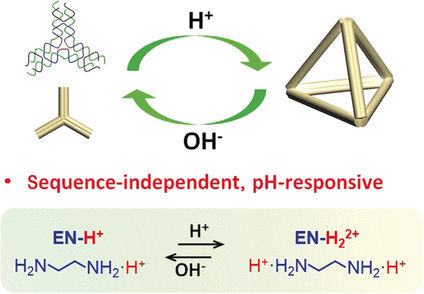

The second key involves "tuning" the DNA structures so that the machines' movements are reversible and repeatable. The researchers dot their structures with synthetic DNA strands that hang off the edges like the awning of a roof. Rather than join portions of the machine together permanently, these strands are designed to act like strips of hook and loop fasteners--they stick together or unstick depending on chemical cues from the machine's surroundings.

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.